What is a transfer sticker?

Transfer stickers are designs (or lettering) that can be installed without a surrounding background shape. It offers a clean and minimalistic appearance, providing a modern and sleek design by eliminating the need for a background shape. Seamlessly integrating with the color of the underlying surface, enhances visual coherence and gives the lettering a professional and sophisticated look suitable for many applications.

However, being without a background shape (one-piece sticker), when it comes time to remove them you will need to remove each piece separately.

Transfer stickers and lettering designs are made up of 3 layers of different materials each with a specific purpose. Detailed description below image.

- Liner Paper: The bottom layer of the sticker is called the release liner or backing liner paper. This is what the next layer, the vinyl adhesive layer, is adhered to during the printing and cutting process.

- Vinyl: The middle layer is the actual cut vinyl design. This can be single-color cut vinyl or full-color printed vinyl transfers.

- Application Tape: The top layer of the sticker is the transfer tape sometimes called application tape. This is a low-tack tape that temporarily holds the individual vinyl pieces when removed from the backing liner paper until transferred and applied to the installation surface.

Liner Paper Backing

The liner paper serves to protect and preserve the vinyl, especially the adhesive side, from our processing until you remove it for installation. It goes by various names such as release liner, backing paper, and liner paper. Typically, liners are made of kraft paper with a 90# paper weight, although there may be variations between manufacturers. While most liners are white or off-white, some may feature a contrasting color to emphasize the specific vinyl color.

Vinyl Materials

Cut Vinyl Transfer Stickers

Cut vinyl refers to non-printed single-color vinyl (black, white, red, etc.). While black and white are the most common choices, we provide a range of colors from various suppliers. One advantage of cut vinyl is that it doesn’t require lamination since no ink is involved.

Most cut vinyl rolls typically feature a gloss finish, although some are offered in a matte finish. We always have black and white in either gloss or matte, but if your project demands a specific color with a matte finish, get in touch with our team to check its availability.

With cut vinyl, the adhesive side matches the face side’s color. For instance, if you opt for cardinal red vinyl, the adhesive side will appear red when viewed from the opposite side, such as in a window.

If you wish to incorporate multiple colors in your installation, you can achieve this through layering with multiple pieces of cut vinyl. However, each piece needs a separate order. In such cases, it might be more practical to consider a full-color printed transfer sticker, as explained in the next section.

Multi-Color Printed Vinyl Transfer Stickers

Full-color or multi-color is our most popular transfer sticker product on Want Stickers offers incredible flexibility for multi-color designs. This makes production easy with few limitations. We print your multi-color or single color design on a white opaque material. If there is no white in your design it is not a problem, because we print your exact design and cut it to the edges.

We can print a vast range of colors, including color gradients on your stickers. However, it’s worth noting that using special effects like drop shadows and outer glows has some limitations. While there are workarounds to incorporate these effects, the results may not always be ideal. Unless you’re well-acquainted with the production process from graphic design to the finished product, we recommend avoiding effects and keeping your designs in a pure vector graphic form.

You can order Custom Transfer Stickers in the linked sticker category. However, there are also transfer sticker products available in other categories on the site, each tailored with specific materials and adhesives for their respective categories.

Lamination

Lamination involves applying an overlaminate to the top of the vinyl to safeguard it from scratches, UV-induced color fading, or edge curling if the chosen adhesive isn’t robust enough for the surface.

This process also increases the overall thickness of your item. Standard lamination effectively doubles the thickness, bringing it to around 5-7 mil.

For most products, lamination comes with options for gloss, semi-gloss, or matte finishes. If your item is likely to face sunlight, outdoor exposure, or regular physical contact, opting for a laminate is advisable.

However, for specific scenarios (like indoor use for 1-2 years, temporary applications, cost considerations, material thickness preferences, adding a clear coat, or if your files don’t meet requirements), you have the option to skip lamination. Keep in mind, though, that items without lamination may not endure as long as their laminated counterparts.

Specialty Materials

Explore specific categories for specialty transfer sticker materials, including frosted etched window film, reflective vinyl, and stickers designed for textured surfaces, among others! If you have a particular material in mind that you’d like to cut into a transfer sticker, reach out to our team to check if we can acquire it for your project.

What is application tape?

Application tape (sometimes referred to as transfer tape) is a material with a low-tack adhesive on one side. This sticky paper or vinyl material was specifically designed to transfer an adhesive vinyl decal to your installation surface.

Once the vinyl backing liner has been removed, the transfer tape then acts as a carrier sheet which allows you to carefully place and position your transfer vinyl decals together.

We supply all transfer stickers with paper or clear plastic application tape already applied and ready for installation! We supply them with the tape that best works with the product type ordered. Currently, all printed transfer stickers are shipped with paper tape, and cut vinyl is shipped with clear tape. Both paper and clear have their pro’s and con’s, but the paper tape is the most versatile application tape for transfer and release of vinyl.

If you have a preference, please let us know and we can test with the material type you are ordering. Although the appearance and tackiness of transfer tape may vary, all of these materials perform the same function: they allow you to easily move and position your vinyl design from its paper backing to your final project.

For larger prints that are rolled up for shipping, you may notice that the tape and vinyl design may slip off of the liner. Creating a ripple or tunnel separation from the liner. This is normal, and once you fully remove the item from the backing liner you can install with ease!

What are the file requirements?

Transfer Sticker items have two main file requirements that must be met. Listed below are the requirements along with a more detailed explanation below.

- Vector Files

- Thickness and Gap Size

If you’re unsure or need help adjusting your graphic designs to meet our requirements, reach out to us. Send us your files for review, and include details about the materials you intend to use and the size you’re ordering. We’re here to assist you.

1. Vector Files

Vector files are made of digital paths, nodes, and curves dictated by mathematical formulas, rather than pixels-based (raster graphics). These shapes are produced exclusively through design software designed for vectors, like Adobe Illustrator, Corel, or Sketch. Because of their algorithmic makeup, vectors can be scaled to any size without losing quality. Elements such as fonts will render the same way once outlined. This means when scaled up or down both elements will remain clean and exact. Vector files are also normally very small in file size.

Common vector graphic types are .ai, .eps, .pdf, or .svg

.jpg, .png, .psd, or .tiff are pixel-based (raster) designs and are not vector formats.

Sometimes even pixel-based designs can be saved as the file types mentioned above. Meaning that the contents inside are not vector graphics.

Typically, you can zoom in when viewing on your computer preview or browser you will begin to see fuzzy or “staircase” pixelation on the edges if it is a pixel-based graphic. If it looks crisp when zoomed in, it is most likely a vector graphic. If you are uncertain, you can send us your files before ordering for review.

It’s possible for us to convert pixel images into vector format for you if they have high enough resolution. We would recommend sending us the files before ordering transfer stickers if you cannot locate a vector file.

If you can open your graphic in Adobe Illustrator, you can click and drag a box around your objects to see vector edges. Another way to view vector objects is to click Outline in the menu bar as shown in the video below.

2. Thickness & Gap Size

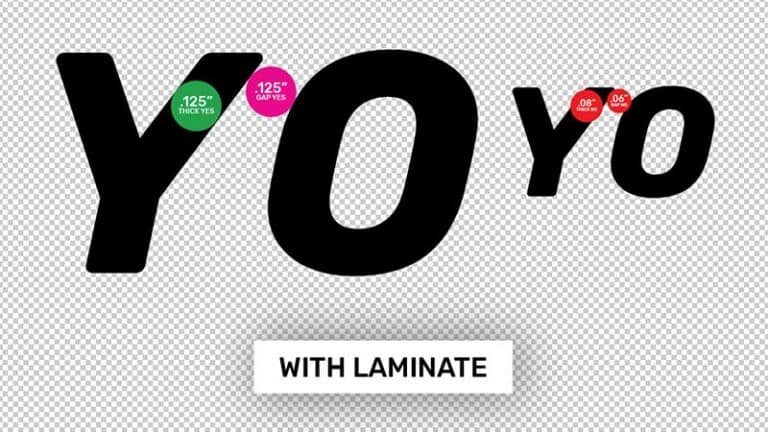

Our general requirement for transfer sticker object sizes is a minimum thickness/gap of .06” (without a laminate) and .125″ (with a laminate).

Below are images that show a guide that we created with a shape to the requirement sizes that can be used to measure the thickness and gaps in your vector graphic design files. For more information refer to our full guide to transfer sticker requirements.

If you’re unsure whether or not your files meet these requirements, our team can help! Just email us the file and the desired size you are looking to order and our graphic design team will review it for you, or make test cuts.

What are inner picks?

Inner picks are the parts of vinyl inside of an enclosed object or graphic that needs to be manually picked out after the design has been cut. For example, the inside of the letter “A” and “R” shown below, vinyl will need to be removed manually. During the checkout process, our website form will ask that you count the number of inner picks in your graphic design being uploaded and select the appropriate option to adjust the pricing of the stickers.

Products In This Article

What can transfer stickers be used for?

Removable and long-term permanent adhesive options, with many uses for most flat surfaces!

- Wall Graphics

- Window Graphics

- Floor Graphics

- Vehicle Body Graphics

- Vehicle Window Graphics

- POP Retail Graphics

- Tradeshow Signs

- Wayfinding Signage

- Storefront Signage

- Lettering